In Proceedings of the environmental impacts of preservative-treated wood conference, Orlando, Florida, 8–10 Feb Lebow S (2004) Alternatives to chromated copper arsenate (CCA) for residential construction. Kogelschatz U (2003) Dielectric-barrier discharges: their history, discharge physics, and industrial applications. Klarhöfer L, Viöl W, Maus-Friedrichs W (2010) Electron spectroscopy on plasma treated lignin and cellulose. Kirkpatrick JW, Barnes HM (2006) Biocide treatments for wood composites-a review.

Hiziroglu S (1996) Surface roughness analysis of wood composites: a stylus method. Hill C (2006) Wood modification, chemical, thermal and other processes. American Chemical Society, Washington, D. In: Goodell B, Nicholas DD, Schultz TP (eds) Wood deterioration and preservation: advances in our changing world. Gardner DJ, Tascioglu C, Walinder E (2003) Wood composite production. Proc Am Wood Preserv Assoc 79:195–205įreeman MH, McIntyre CR (2008) A comprehensive review of copper-based wood preservatives. Wood Sci Technol 42(3):251–265įiest WC (1983) Weathering and protection of wood.

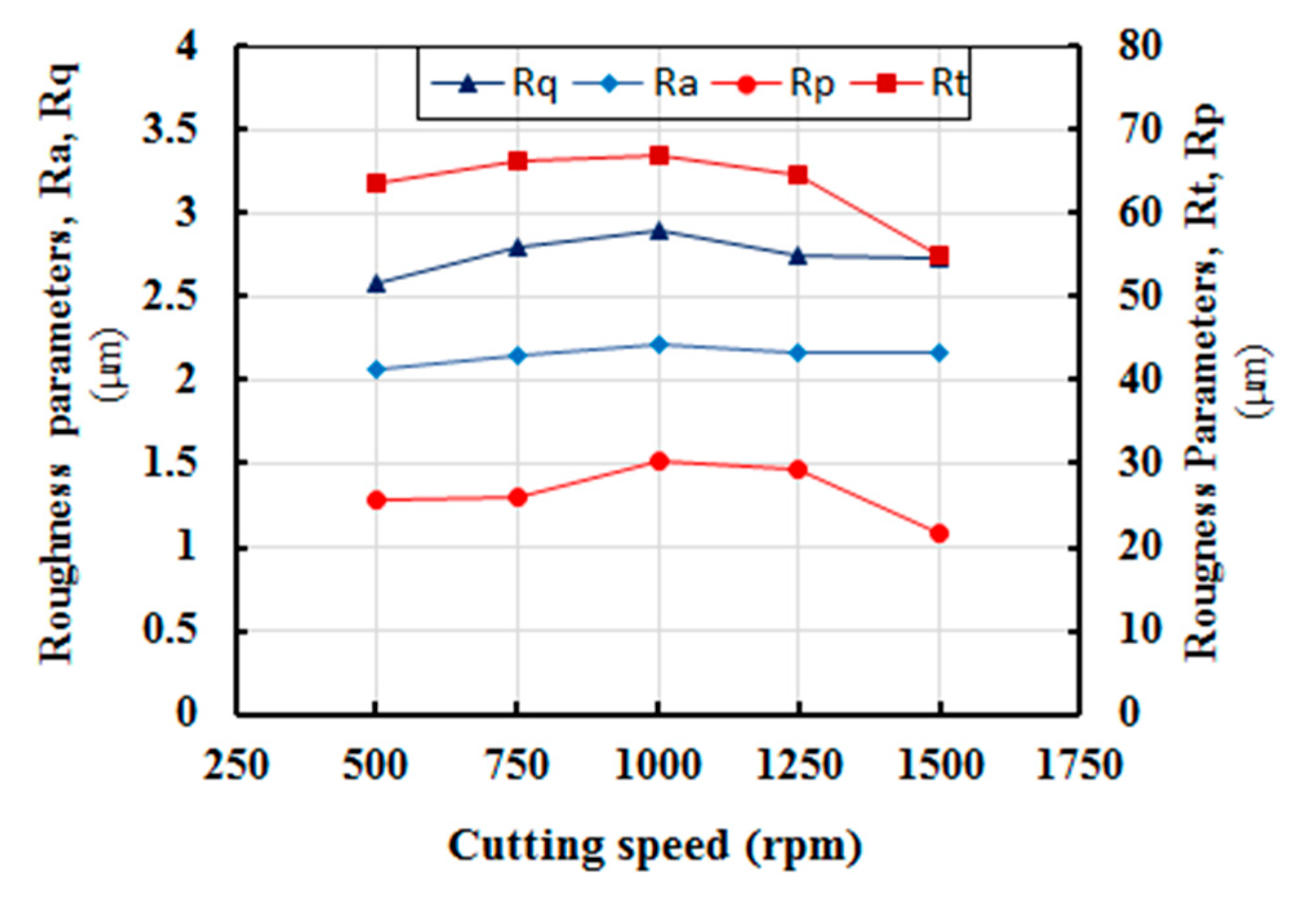

European Committee for Standardization, Brussels-BelgiumĮvans PD, Urban K, Chowdhury MJA (2008) Surface checking of wood is increased by photodegradation caused by ultraviolet and visible light. European Committee for Standardization, Brussels-BelgiumĮN-314-1 (1993) Plywood-bonding quality-part 1: test methods. Holzforschung 60(1):40–46ĮN 310 (1993) Wood based panels, determination of modulus of elasticity in bending strength. Wood Sci Technol 38:555–566ĭonath S, Militz H, Mai C (2006) Creating water-repellent effects on wood by treatment with silanes. Deutsches Institut für Norming, Berlin, Germany (withdrawn)ĭonath S, Militz H, Mai C (2004) Wood modification with alkoxysilanes. Turk J Agric For 38:663–667ĭIN 4768 (1990) Determination of values of surface roughness parameters Ra, Rz, Rmax using electrical contact (Stylus) instruments, concepts and measuring conditions. Wood Sci Technol 42(1):5–20ĭemirkir C, Aydin I, Colak S, Colakoglu G (2014) Effects of plasma treatment and sanding process on surface roughness of veneers. Int J Adhes Adhes 29(2):167–172ĭeka M, Humar M, Rep G, Kričej B, Šentjurc M, Petrič M (2008) Effects of UV light irradiation on colour stability of thermally modified, copper ethanolamine treated and non-modified wood: EPR and DRIFT spectroscopic studies. R 36(5–6):143–206Ĭustódio J, Broughton J, Cruz H, Winfield P (2009) Activation of timber surfaces by flame and corona treatments to improve adhesion. Wood Fiber Sci 41(3):245–254Ĭhu PK, Chen J, Wang LP, Huang N (2002) Plasma-surface modification of biomaterials. Plasma Chem Plasma P 30(5):697–706īlanchard V, Blanchet P, Riedl B (2009) Surface energy modification by radiofrequency inductive and capacitive plasmas at low pressures on sugar maple: an exploratory study. Wood Sci Technol 45(2):359–368Īydin I, Demirkir C (2010) Activation of spruce wood surfaces by plasma treatment after long terms of natural surface inactivation. Holzforschung 2:223Īvramidis G, Scholz G, Nothnick E, Militz H, Viöl W, Wolkenhauer A (2011) Improved bondability of wax-treated wood following plasma treatment. Int J Adhes Adhes 32:70–75Īsandulesa M, Topala I, Dumitrascu N (2010) Effect of helium DBD plasma treatment on the surface of wood samples. Ground contact test revealed that there was no delamination in bonding line on the plasma-treated samples.Īcda MN, Devera EE, Cabangon RJ, Ramos HJ (2012) Effects of plasma modification on adhesion properties of wood. Regarding leaching test, plasma treatment slightly increased the leaching rate of copper in some groups.

However, plasma treatment slightly increased the mass losses caused by white rot, but decreased mass losses caused by brown rot in some groups. Results showed that plasma treatment with O 2 increased the bonding strength of plywood compared to control and treated groups. Surface roughness, leaching, decay test against white ( Trametes versicolor) and brown rot and ground contact test of plywood samples were evaluated after plasma treatment. The effect of plasma treatment on bonding shear strength, bending strength and modulus of elasticity of plywood panels were determined according to EN 314-1 and EN 310, respectively. Two types of gasses (O 2 and N 2) were tested for plasma treatment. Veneers were obtained from beech logs ( Fagus orientalis L.) and treated with 3 % of Tanalith E and Celcure AC-500. The effect of plasma treatment on strength properties of wood-based composites was studied.

0 kommentar(er)

0 kommentar(er)